PREVENTIVE MONITORING SOLUTIONS FOR STRUCTURES

USING THRESHOLD DETECTION VIA ENERGY-FREE MEMS SENSORS

MECHANICAL LOADS

SHOCKS & ACCELERATIONS

TEMPERATURE

ChronoMEMS is a family of hybrid MEMS micromechanical sensors that operate without power, designed for monitoring structures and equipment. They detect and/or count mechanical or thermal events 24/7 according to predefined thresholds, all without any electrical power supply and over several decades..

Adopt a threshold-based monitoring approach,

adapted to operational constraints over long periods of time.

THRESHOLD EXCEEDANCE DETECTOR

CYCLE COUNTERS BY THRESHOLD

SHOCK SENSOR CATALOGUE

You want to know if your product shipments, or your products, have experienced a shock/fall?

Contact us to discover our shock monitoring solutions

CATALOGUE OF SHOCK SENSORS

Vous souhaitez savoir si vos envois de produit, ou vos produits, ont subi un choc/une chute ?

Contactez-nous pour découvrir nos solutions de monitoring des chocs sans énergie.

MICRO SENSORS WITH DISRUPTIVE CHARACTERISTICS

OPERATIONAL 24/7

Over very long periods of time (decades)

IMMEDIATE EXPLOITATION

Little to no post-processing

UNFAILING DATA

Our sensors are insensitive to the frequency of occurrence of events, and collect only the data essential to the operation of a structure or the monitoring of a critical part.

ZERO MAINTENANCE

No calibration, no drift

RAW DATA AVAILABLE AT ALL TIMES

The data is stored mechanically in the sensor, with no risk of losing it.

LOW ENVIRONMENTAL IMPACT

Our sensors are purely mechanical and do not require any power source to operate.

LECTURE FACILE

EASY READING & EASY UTILISATION

Several levels of readers are possible: direct optical consultation (without energy), passive RFID (without energy), or connected sensors (energy-free sensors, connected bricks).

COMPATIBLE WITH SEVERE ENVIRONMENTS

Our sensors are designed to withstand extreme conditions: aeronautical, space, military, explosive, radiative environments, etc.

MINIMAL CARBON IMPACT | An energy-free solution that collects, transmits, and stores very little data*, requiring minimal post-processing: this unique operating principle allows for a reduction of up to 97% in greenhouse gas emissions (compared to existing solutions)

*ChronoMEMS communicator

WHY CHOOSE CHRONOMEMS?

The energy-free solutions from SilMach have been developed for operational monitoring purposes rather than curative monitoring. Each use case must be linked to an operational need. Typical uses include: drift from nominal behaviour, detection of accidental loading, unexpected service conditions, etc.

PREVENTIVE MONITORING OF EQUIPMENT AND STRUCTURES

Detection and/or counting of a threshold exceedance related to continuous operational monitoring under service conditions.

“EVENT-BASED” ALERTS

The sensor continuously monitors the service conditions in real time. As soon as a critical threshold is exceeded, the sensor acts like a smart switch that can instantly trigger an alert or a dedicated operational procedure.

MULTIPLE APPLICATIONS

CRITICAL AEROSPACE PARTS

Structural fatigue monitoring, shock analysis, on rotating parts and parts subjected to high mechanical stresses

BRIDGES AND ENGINEERING STRUCTURES

Structural fatigue monitoring, excessive load counting, joint opening, cracks

des charges excessives, ouverture de joints, fissures

LIFTING EQUIPMENT

Maximum load monitoring, cycle counting

MILITARY EQUIPMENT

Fatigue monitoring, shock detection on protective equipment, shot counting, temperature

RAILWAY EQUIPMENT

Monitoring of bogies, detection of abnormal events

MEDICAL EQUIPMENT

Shock and temperature on critical equipment and consumables

TRANSPORT & LOGISTICS

Monitoring of Critical Shocks and Temperature on containers, pallets and cartons

INDUSTRIAL EQUIPMENT AND PRECISION TOOLS

Monitoring of mechanical wear, detection of shocks and deformations

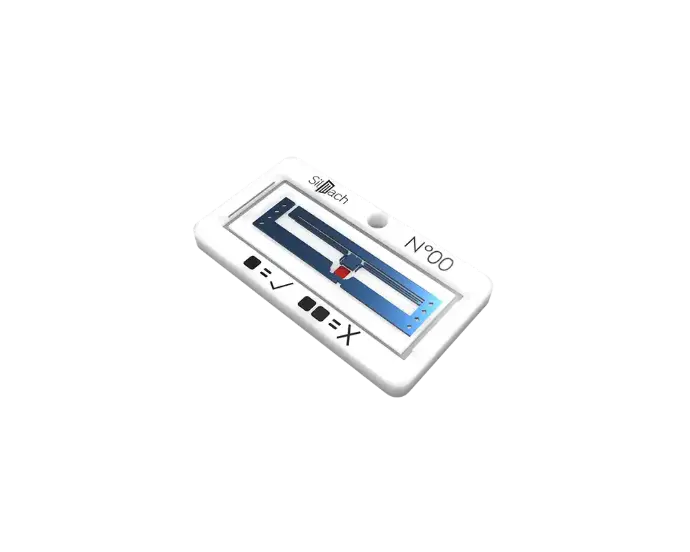

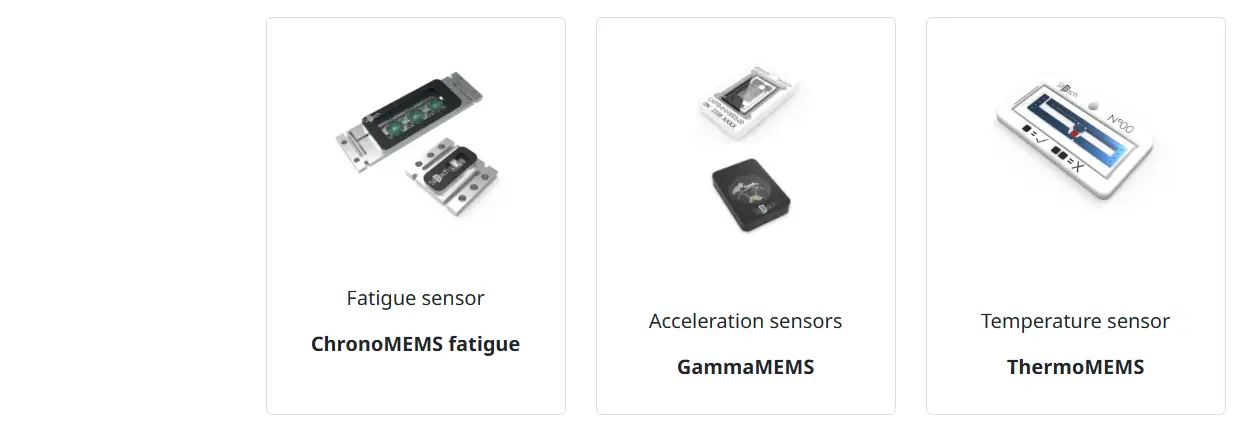

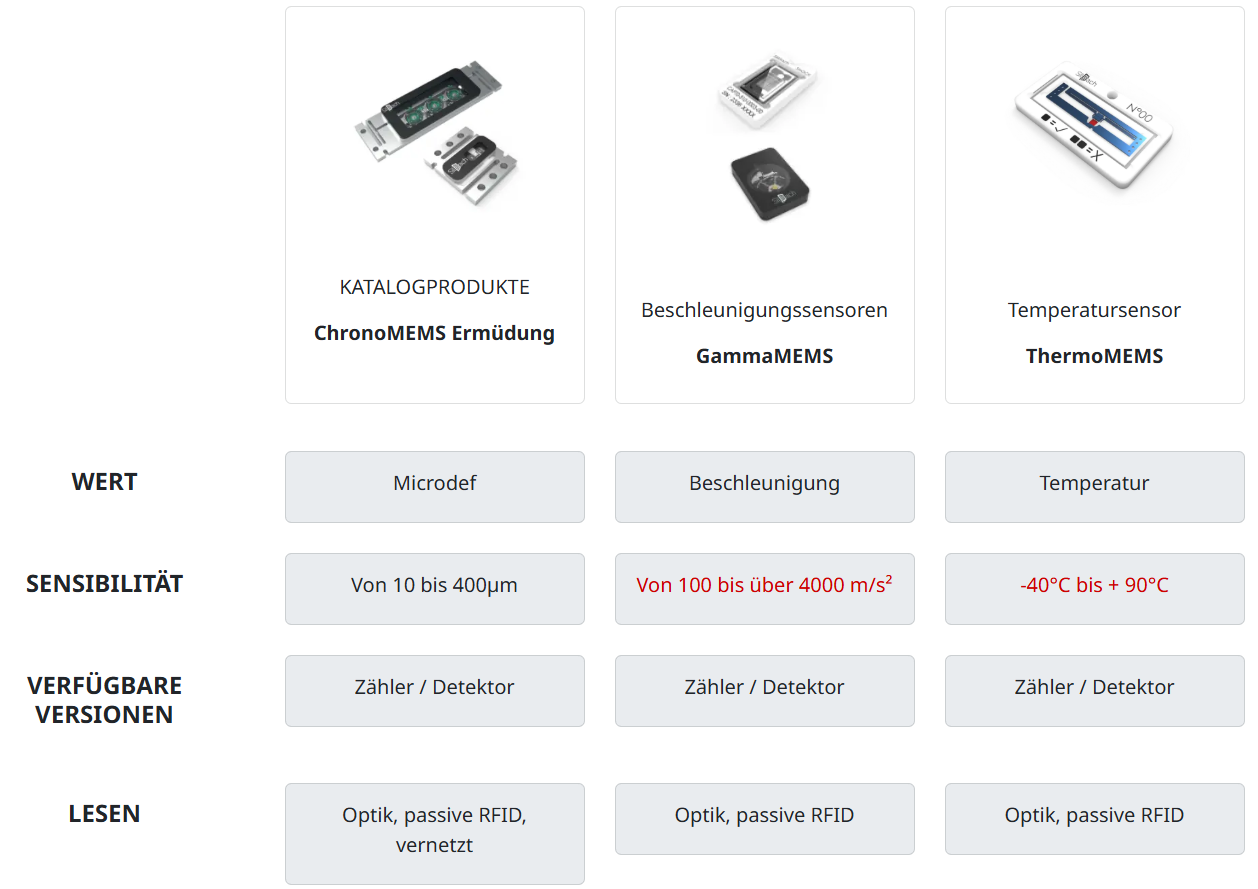

PRODUCTS CATALOGUE

PRODUCTS CATALOGUE

Fatigue, crack, pressure

ChronoMEMS fatigue

Impacts, falls, acceleration

GammaMEMS

Temperature exceedance

ThermoMEMS

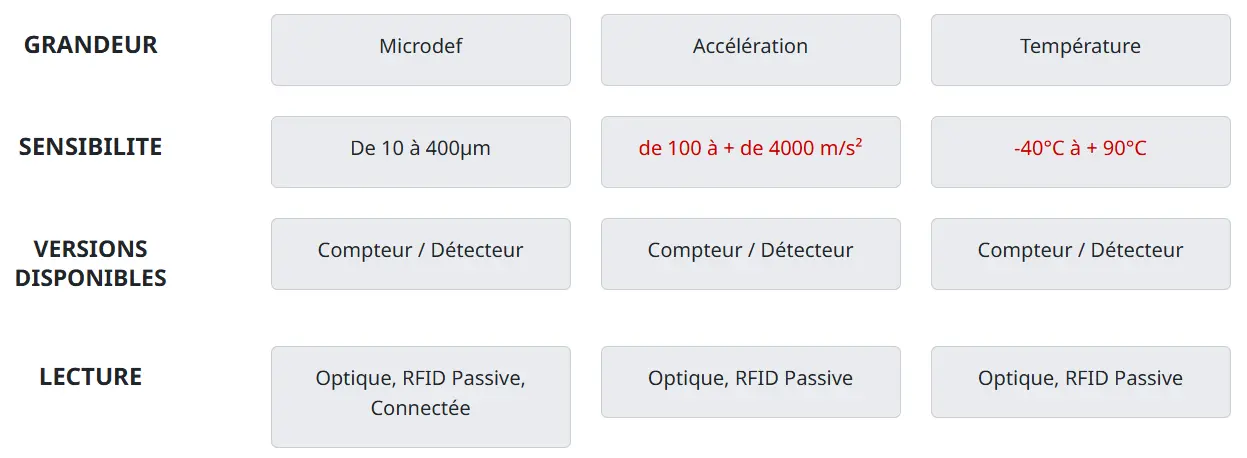

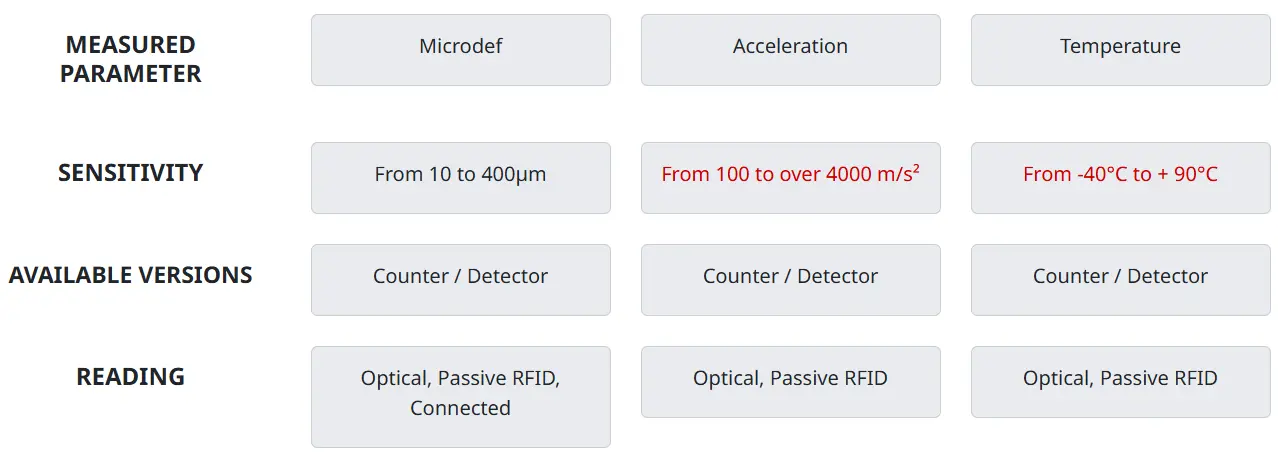

MEASURED PARAMETER

Microdef

Acceleration

Temperature

SENSITIVITY

From 10 to 400µm

From 100 to over 4000 m/s²

From -40°C to + 90°C

AVAILABLE VERSIONS

Counter / Detector

Counter / Detector

Counter / Detector

READING

Optical, Passive RFID, Connected

Optical, Passive RFID

Optical, Passive RFID

Our R&D teams are continuously improving our sensors and their functionalities. Please feel free to contact us to learn more or to present your specific needs.

Our R&D teams are continuously improving our sensors and their functionalities. Please feel free to contact us to learn more or to present your specific needs..

Deeptech pioneers of hybrid MEMS and experts in silicon component manufacturing since 2003

ADRESS

SA SILMACH

16 RUE SOPHIE GERMAIN

25000 BESANCON

FRANCE